Machine vision inspection is revolutionizing the way industries approach quality control and automation. By integrating cameras and software, machine vision systems can accurately and efficiently inspect products and processes. In this article, we’ll explore what machine vision inspection is, how it works, its benefits, and its applications across industries. For an in-depth understanding, check out this comprehensive guide on machine vision inspection.

What Is Machine Vision Inspection?

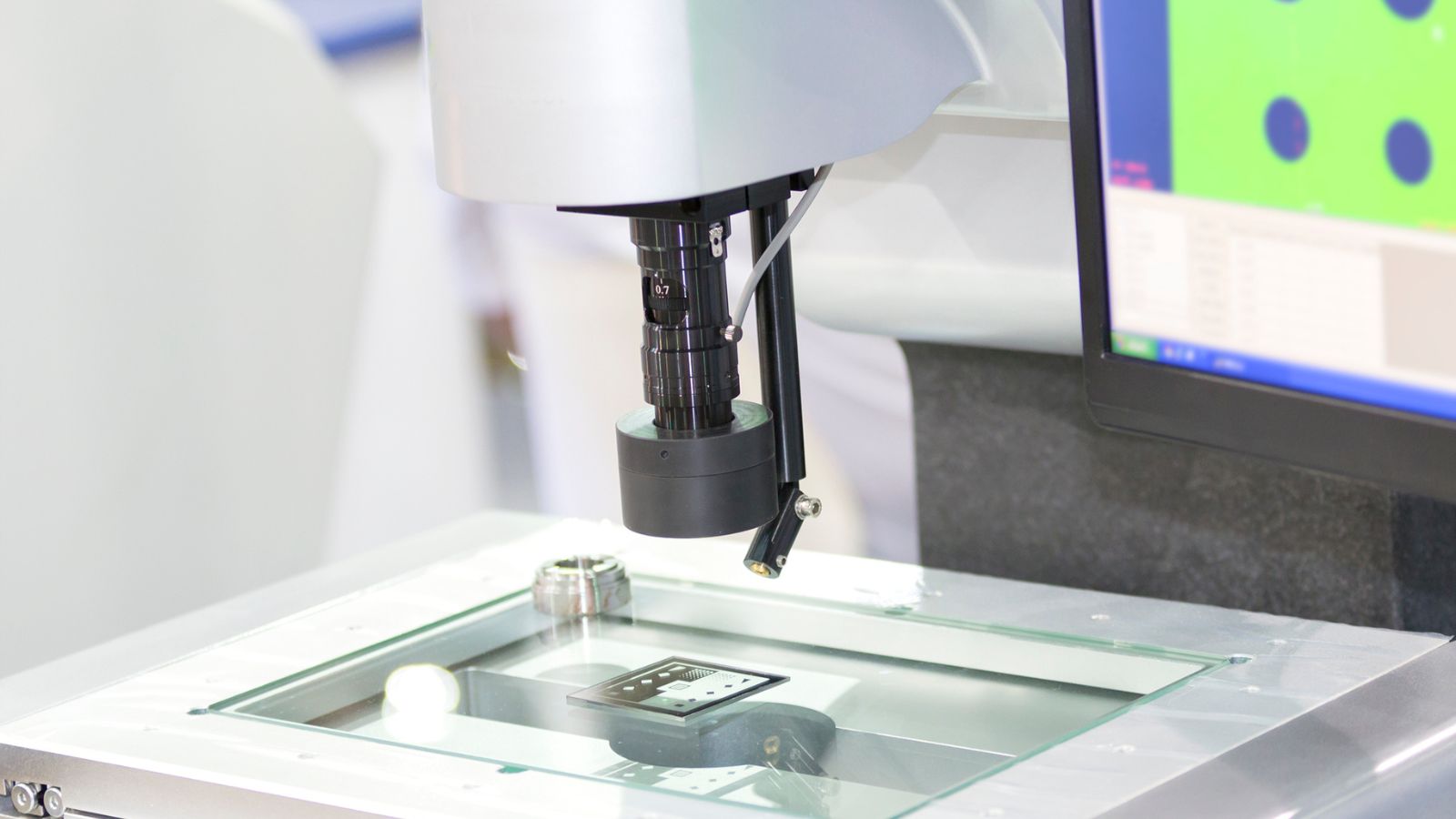

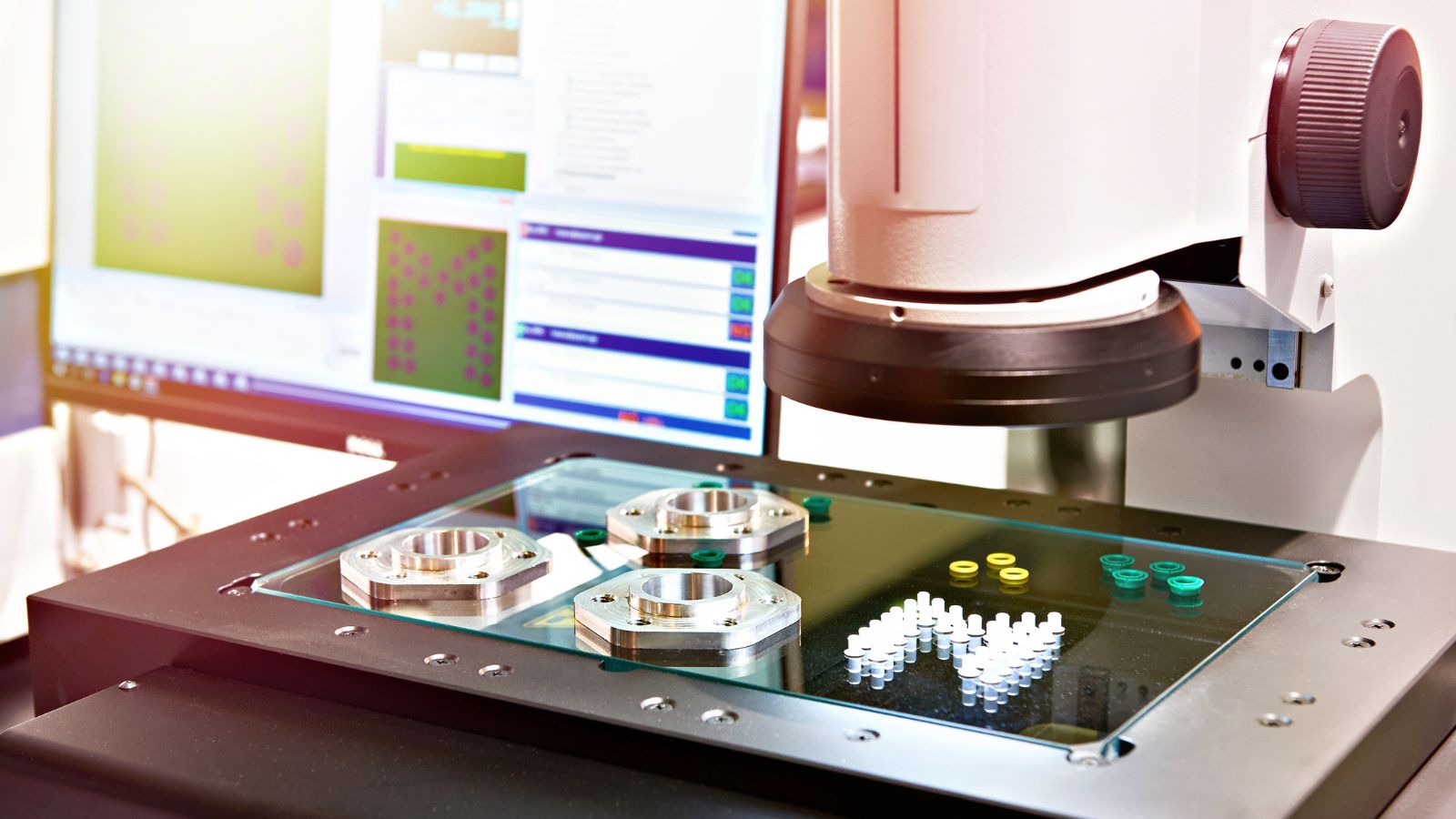

Machine vision inspection uses computer vision technologies and techniques to inspect and analyze objects automatically. It involves capturing images via cameras, processing them using software, and making decisions based on pre-set criteria. This technology is widely used in industrial settings for quality control, ensuring that products meet specific standards without human intervention.

Key Components Of Machine Vision Systems

Machine vision systems consist of several key components that work together to perform inspections:

- Camera: Captures images of the product or area to be inspected. Cameras can be 2D or 3D, depending on the complexity of the inspection.

- Lighting: Ensures the optimal illumination of the object for accurate image capture.

- Image Processing Software: Analyzes the captured images to detect defects, measure dimensions, or identify features according to the inspection criteria.

- Processor: Interprets the data from the image processing software to make real-time decisions.

- I/O Interfaces: The machine vision system can communicate with other devices like alarms, robots, or conveyor belts.

How Does Machine Vision Inspection Work?

The process of machine vision inspection typically involves several steps. First, the system captures one or more images of the product using cameras. Next, these images are enhanced and analyzed using sophisticated algorithms in the image processing software. The system then compares the extracted data against predetermined criteria or dimensions to identify discrepancies or defects. Finally, based on the analysis, the system triggers a response, such as sorting out defective products or alerting operators.

Benefits Of Machine Vision Inspection

The adoption of machine vision inspection offers numerous advantages:

- Increased Accuracy: Machines can detect even the smallest defects or variations that human inspectors might miss.

- Consistency: Machine vision ensures uniform inspection across all products, reducing the variability found in human inspection.

- Speed: Machine vision systems can inspect products at high speeds, facilitating faster production rates without compromising quality.

- Cost-Effective: By minimizing manual inspection, businesses can reduce labor costs and increase operational efficiency.

- Scalability: Once implemented, machine vision systems can handle increased production volumes without additional resources.

Applications Of Machine Vision Inspection

Machine vision inspection is utilized across a variety of industries to enhance product quality and process efficiency:

Automotive Industry

In the automotive sector, machine vision inspection is employed for tasks such as detecting surface defects, ensuring precise assembly of components, and verifying paint quality. These systems ensure that vehicles meet strict safety and quality standards.

Electronics Manufacturing

Machine vision systems are critical in electronics manufacturing, where they inspect printed circuit boards (PCBs) for soldering defects, component placement, and connectivity issues, ensuring reliable and high-performance electronic products.

Food And Beverage Industry

In the food and beverage industry, machine vision inspection ensures the quality and safety of consumer products. Systems can inspect packaging integrity, label accuracy, and the presence of foreign objects, enhancing consumer safety and brand trust.

Pharmaceutical Industry

Pharmaceutical companies use machine vision systems to verify the correct labeling of medication, inspect the integrity of packaging, and ensure compliance with regulatory standards to safeguard patient safety.

Conclusion

Machine vision inspection is a transformative technology that significantly enhances the quality control process in various industries. By providing accurate, consistent, and cost-effective inspection solutions, businesses can ensure product quality, increase production efficiency, and maintain competitiveness in the market. As technology continues to evolve, the applications and capabilities of machine vision systems are expected to expand, driving further innovation and excellence.